Magnetic Particle Inspection (MPI)

& Load Testing

Quality Control Methods

Magnetic Particle Inspection (MPI):

Magnetic Particle Inspection (MPI) and load testing are essential quality control methods for ensuring the safety and performance of remanufactured oilfield handling tools. These methods are utilized by companies such as Power Unit Builders and Handling Tools, LLC, which specialize in the remanufacturing and repair of oilfield equipment.

MPI is a non-destructive testing technique that uses magnetic fields and iron particles to detect surface and near-surface flaws in ferromagnetic materials. Load testing verifies the strength and durability of equipment by applying controlled loads to simulate operational conditions.

For more information on remanufacturing and quality control for oilfield handling tools, click here.

Third-Party •

Magnetic Particle Inspection & Load Testing

Magnetic Particle Inspection • MPI

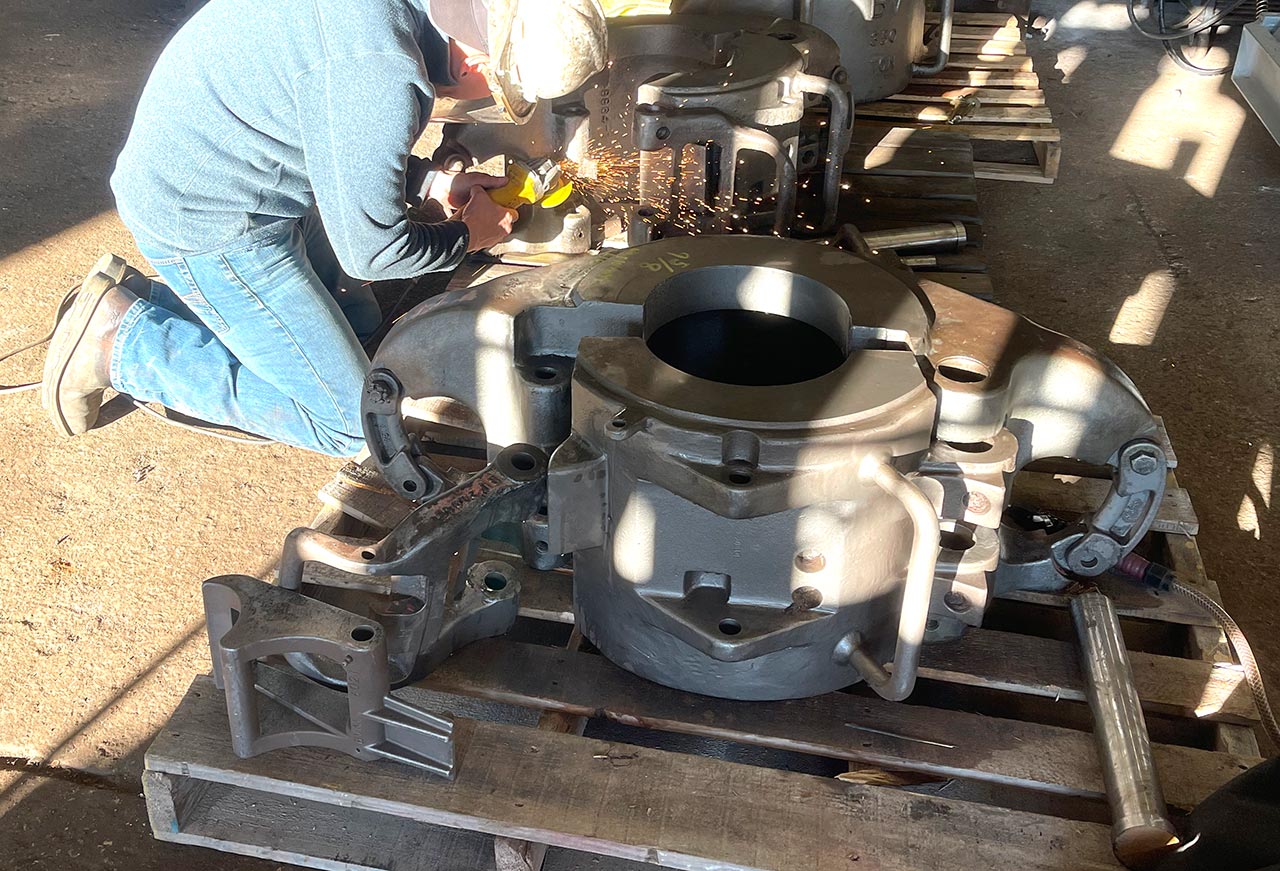

Magnetic Particle Inspection (MPI) and load testing are critical quality control methods used in the remanufacturing (REMAN) of oilfield handling tools. These methods ensure that the tools meet safety and performance standards for use in the oilfield. Here's an overview of how these processes is applied in REMAN:

- MPI is used to detect surface and near-surface flaws such as cracks, seams, and inclusions in ferromagnetic materials.

- It helps ensure the integrity and safety of remanufactured oilfield handling tools.

- Cleaning: The surface of the tool is thoroughly cleaned to remove any contaminants.

- Magnetization: The tool is magnetized using a magnetic field.

- Application of Particles: Ferromagnetic particles (dry or wet) are applied to the surface of the tool.

- Detection: The particles accumulate at areas of discontinuity, such as cracks, creating visible indications.

- Inspection: A trained inspector evaluates the indications to identify potential flaws.

-

Purpose:

-

Process:

Magnetic Particle Inspection (MPI) and load testing are essential quality control methods for ensuring the safety and performance of remanufactured oilfield handling tools. These methods are utilized by companies such as Power Unit Builders and Handling Tools, LLC, which specialize in the remanufacturing and repair of oilfield equipment. Contact Power Unit Builder & Handling Tools for details.

Third-Party Load Testing

- Load testing verifies that remanufactured oilfield handling tools can handle the expected loads during operation.

- It ensures the structural integrity and safety of the tools.

- Set-up: The tool is secured in a test rig.

- Application Load: A controlled load is applied gradually to the tool, often up to and beyond its rated capacity.

- Measurement: The load, deformation, and other parameters are measured and monitored.

- Evaluation: The tool's performance underload is evaluated to ensure it meets the required specifications.

- Load testing verifies that remanufactured oilfield handling tools can handlLoad testing provides confidence in the tool's ability to perform safely under operational conditions.

- It helps identify any weaknesses or areas of concern that may need further attention

- Load testing is performed according to industry standards and guidelines, such as API standards for oilfield equipment.

-

Purpose:

-

Process:

-

Benefits:

-

Compliance:

Both MPI and load testing are essential quality control methods in the remanufacturing of oilfield handling tools. They help ensure that the tools are safe, reliable, and meet the necessary industry standards for use in demanding oilfield environments. Contact Power Unit Builder & Handling Tools for details.